KIAC Kojima Industries Asia Corporation Ltd.

Kojima Industries Asia Corporation Ltd.

A member of the manufacturing sector of a leading auto part manufacturer from Japan, is an International Business Centre (IBC), handles technical and office management support for other members.

Business Information

| Company Name | Kojima Industries Asia Corporation Ltd. |

| Short Name | KIAC |

| Location | 485 Moo. 4 Tambol U-Thai,Amphur U-Thai,Ayutthaya 13210 (Rojana Industrirl Park 3) |

| Telephone | (035) 800-956-63 |

| Facsimile | (035) 800-971 |

| Establishment | 23 July 2020 |

| Paid Capital | 43,600,000 Million Baht |

| Factory Area | – |

| Building Area | 840 sq m. |

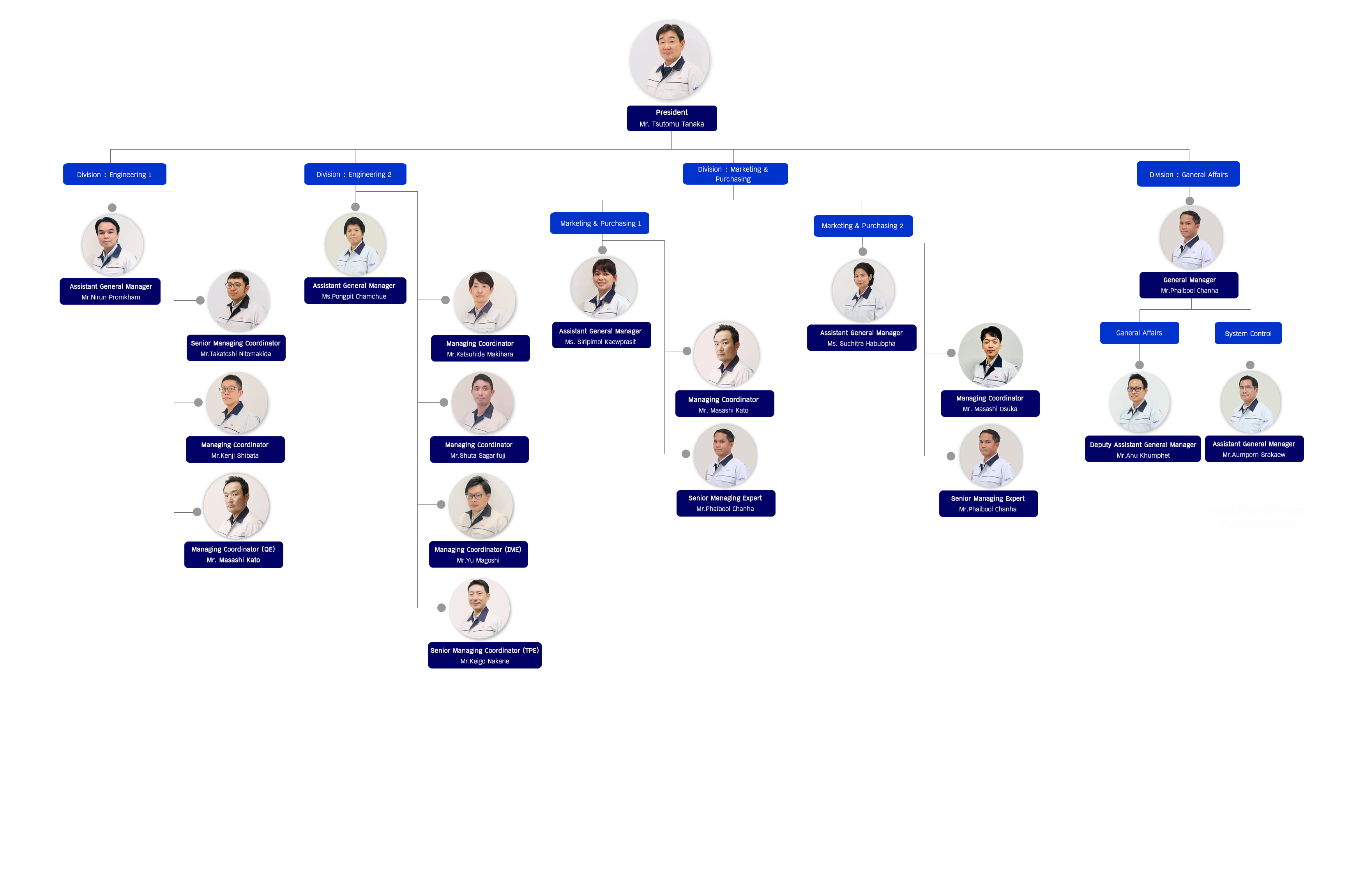

Organization Chart

Members of Kojima group work under the core pillar which we call “One-business”, the management philosophy that accommodates a strong and sturdy network within the group.

KIAC Service

Kojima Industries Asia Corporation Ltd. provided a strong support for the solid foundation of the business by the excellent services.

Recruitment & Selection service

Supporting the human resource, we recruit and select the potential employee. Additionally, we manage the personnel for the Kojima Group.

IT Service (Information Technology)

Information Technology service by professional employees for enhancing the quality of manufacturing processes to reach cost efficiency.

Coordination service

Coordinate between clients and suppliers in order to deliver the product with the perfect condition on time.

Mold production technology

Kojima Auto Technology maximises its productivity using CAD CAM CAE software in a mold manufacturing process. These computer programmes replace the manual drafting and imitate the view of product features and capacity before forwarding to the next process.

Test Mold machines perform at the end of the manufacturing to ensure that product’s pressure quality meets the requirement. Those machines have more than 24-hour working efficiency.

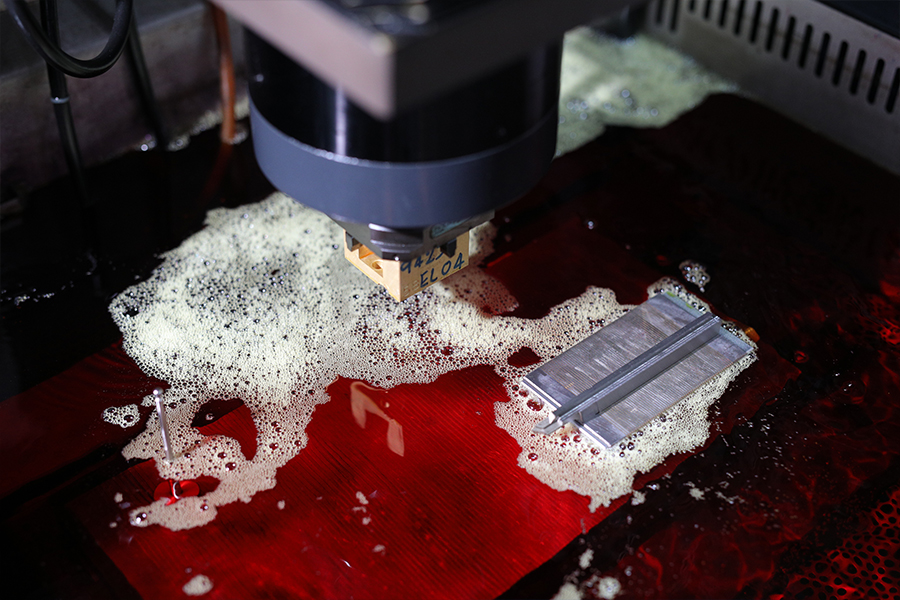

CNC machine

High precision for cutting the workpiece.

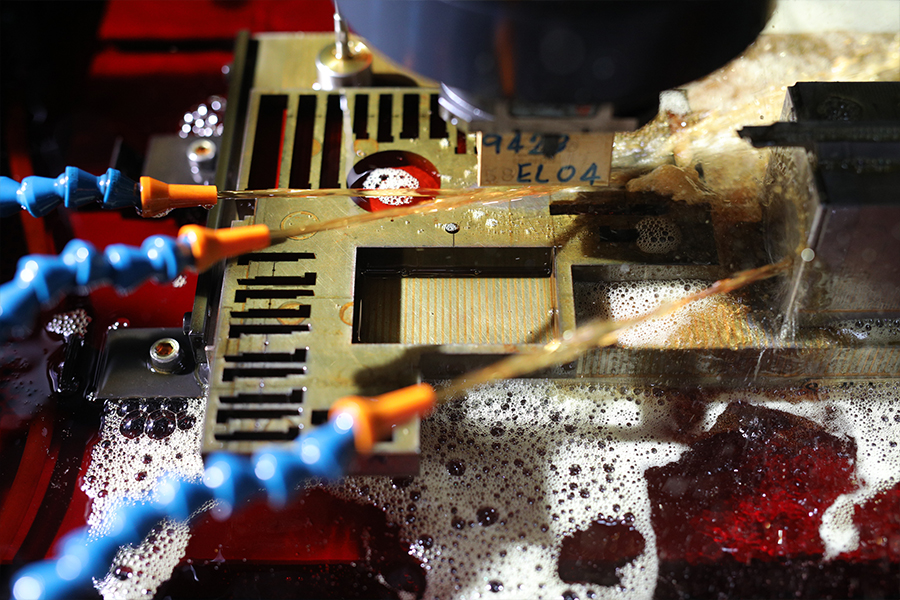

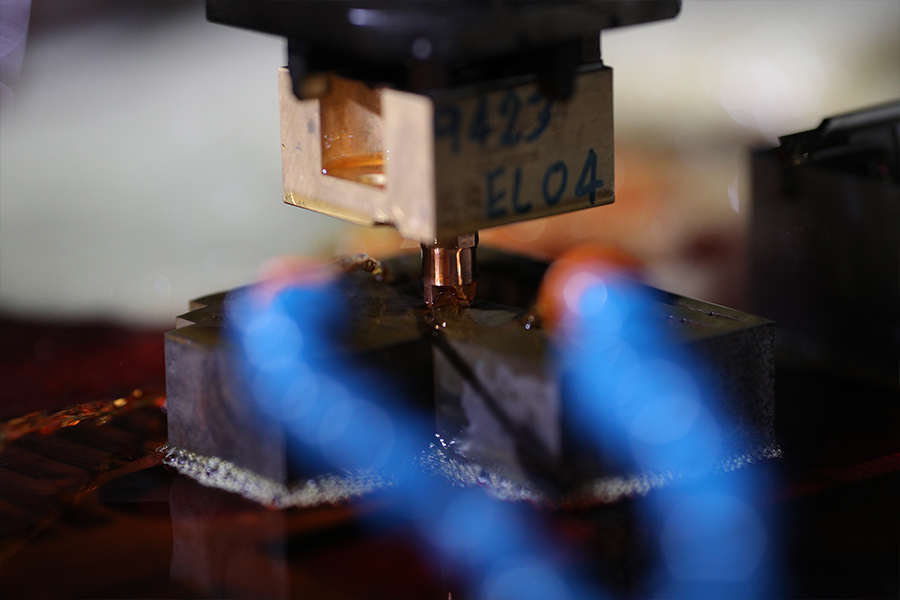

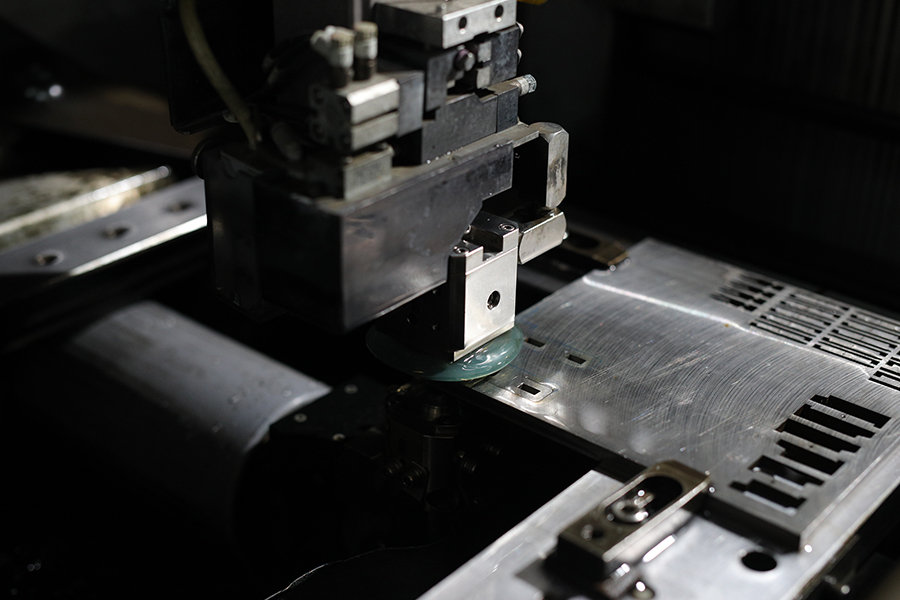

EDM machine

Spark technique based in CAD program, the result is a customized shape of the workpiece.

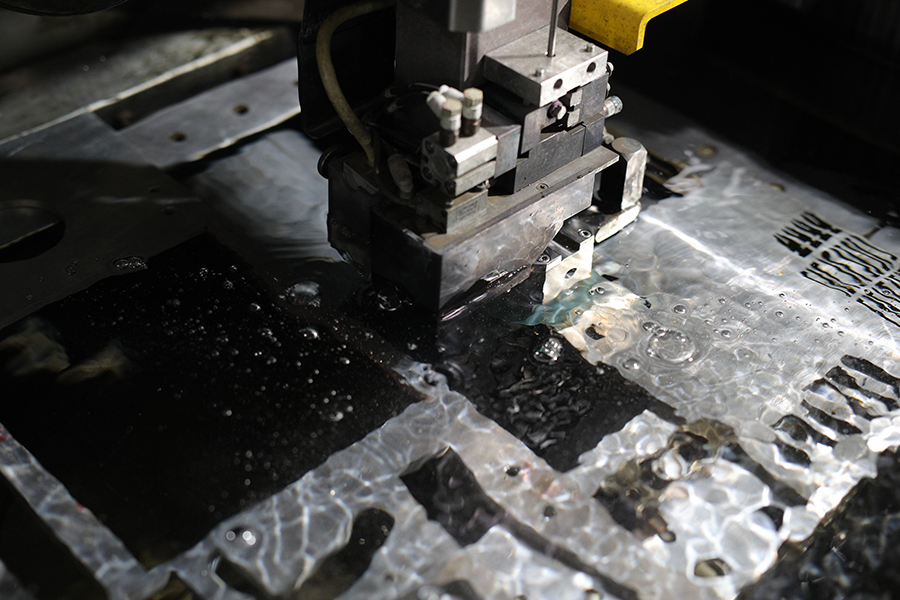

Wire cut machine

using metallic wire to cut or shape a workpiece as designed.

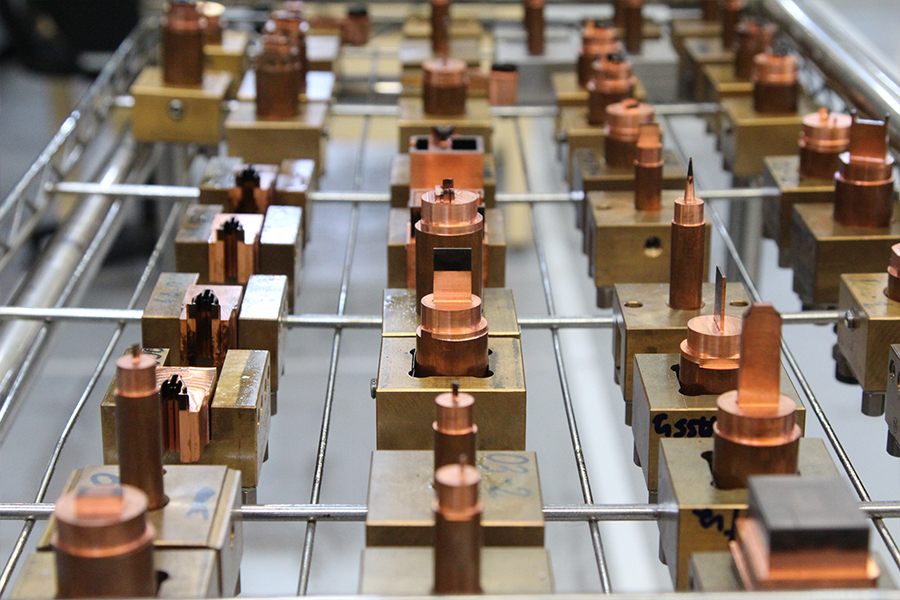

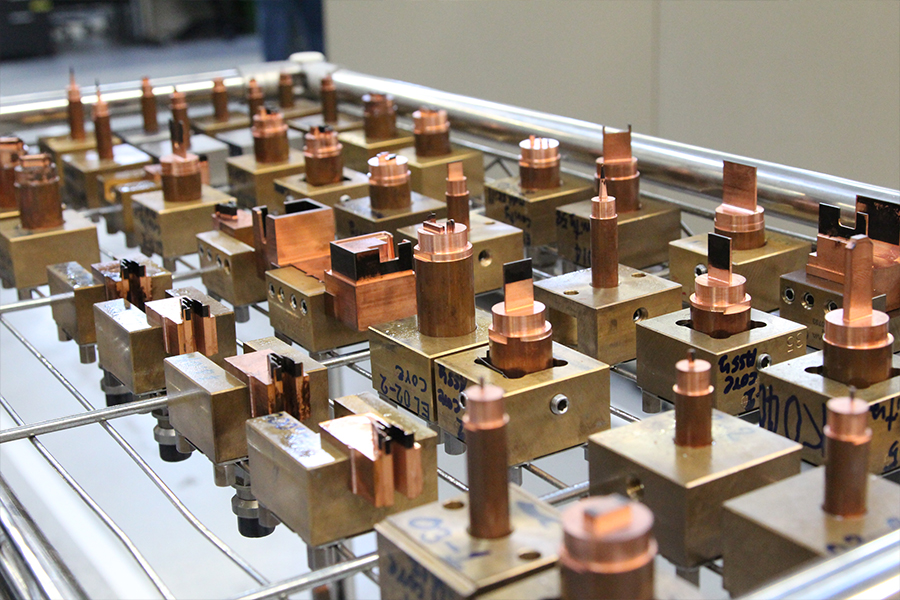

Electrode

The various shapes are designed for producing a complex mold.